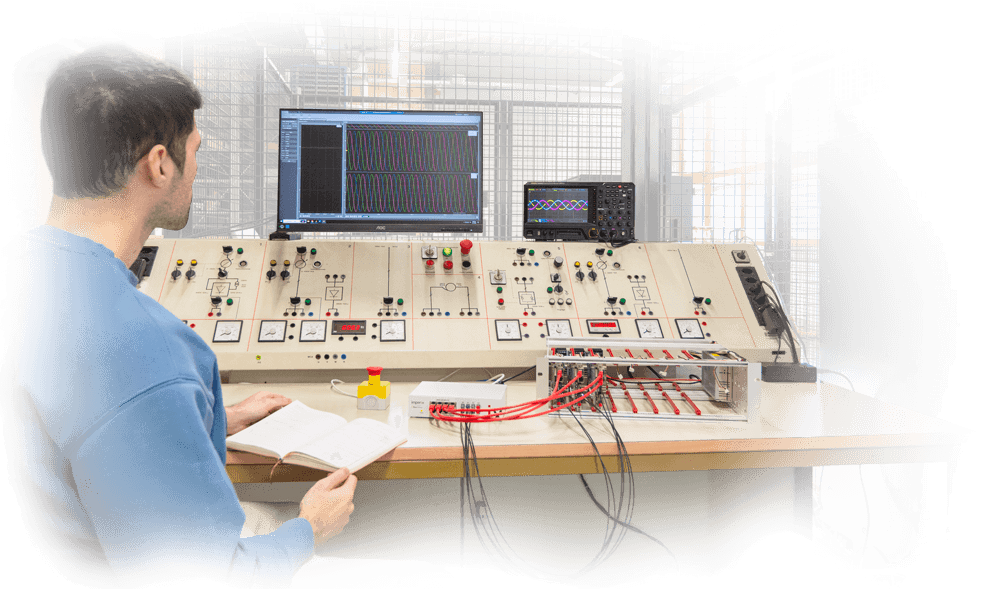

A CONTROLLER TAILORED FOR TEACHING APPLICATIONS

The B-Box Micro is the little brother of the B-Box RCP 3.0. It is tailored for conventional power electronic applications that do not require extensive I/O capabilities. The B-Box Micro is hence ideally suited for use in laboratory research or teaching applications.

The B-Box Micro and the B-Box RCP 3.0 share the same I/O interfaces. Hence, both controllers are directly plug-&-play with imperix power modules. Besides, both controllers can also be programmed using the same easy-to-use Simulink/PLECS blockset and Cockpit monitoring software.

POWER INVERTER CONTROLLER

B-BOX MICRO

The B-Box Micro is a table-top power inverter controller that is directly compatible with imperix power modules.

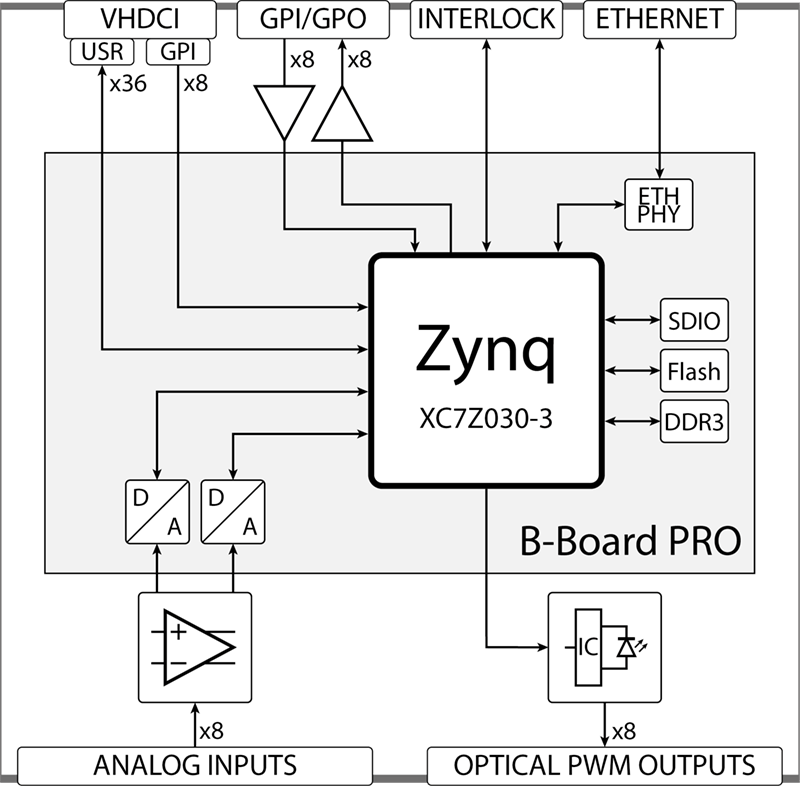

The device is the third member of the imperix controllers family, leveraging the capabilities of the B-Board PRO as a cost-effective alternative to the B-Box RCP 3.0.

BUILD UP A CONVERTER IN THREE HOURS!

The B-Box Micro cannot only serve as a power inverter controller. It can effectively drive any power stage with up to eight PWM signals and eight analog measurements. When used in combination with imperix power modules, everything is even 100% plug-&-play!

SELECT THE EQUIPMENT

such as power modules, sensors, and controller.

BUILD THE ELECTRIC CIRCUIT

using the available enclosures and DIN rails.

CONNECT THE CONTROL SIDE

by simply wiring the plug-&-play connections to the B-Box Micro.

TEST THE OPERATION

generating control from an existing Simulink / PLECS scheme.

PLUG-&-PLAY WITH POWER MODULES

With imperix modules, as well as current and voltage sensors, the B-Box Micro simplifies, speeds up, and secures the implementation of tests in real laboratory conditions.

PART OF IMPERIX ECOSYSTEM

The B-Box Micro guarantees effortless compatibility with imperix products, but also with a wide range of application examples, providing detailed, step-by-step guidance for any level of experience.

SMALL BUT MIGHTY

The B-Box Micro features a robust design and incorporates a multi-layered protection scheme. This ensures a «student-proof» experience and empowers students to learn from mistakes in a worry-free environment.

CONNECTIVITY FOR CONVERTER CONTROL

Through its I/O connectivity, the B-Box Micro guarantees plug-&-play compatibility with other imperix products. Furthermore, the convenient form factor of the table-top controller makes it possible to save space on laboratory stations.

FRONT VIEW

REAR VIEW

INVERTER CONTROLLER SPECIFICATIONS

The specifications of the B-Box Micro are tailored to support state-of-the-art applications in single converter configurations. The controller also offers the same high-performance signal processing system as its bigger brother, the B-Box RCP 3.0.

For more demanding configurations, the B-Box RCP 3.0 offers extended I/O capabilities as well as extreme scalability thanks to networked control options.

| System on chip | Xilinx Zynq XC7Z030-3FBG676E | PWM outputs | Optical 50 Mbps x8 |

| Processing system | ARM Cortex A9 1GHz x2 1GB DDR3 | User High-speed I/Os | FPGA direct (3.3V) x36 |

| Programmable logic (FPGA) | Kintex 7 125K (user programmable) | General-purpose digital inputs | Electrical (5V / 3.3V) x8 / x8 |

| Storage | Flash 16 MB x2 micro SD + eMMC 8 GB | General-purpose digital outputs | Electrical (5V) x8 |

| Communication | Ethernet 1 Gbps x1 | Fault inputs / outputs | Electrical interlock (5V) x1 |

| Analog inputs | 16 bits, simultaneous sampling x8 2Msps (maximum speed) | Incremental decoder inputs | 3-pins (A,B,Z) x4 Shared with GPI inputs |

POWER INVERTER CONTROLLER

A COMPREHENSIVE SOFTWARE ENVIRONMENT

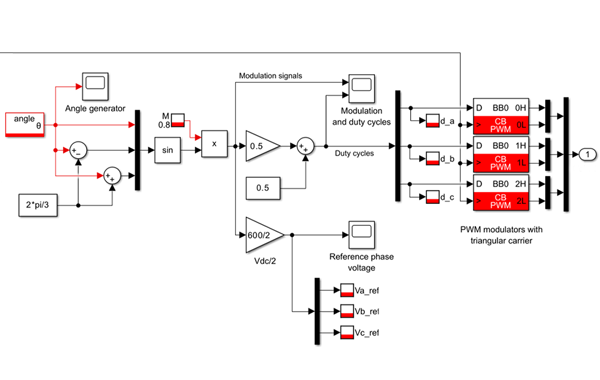

Graphical programming with Simulink and PLECS

The B-Box Micro power inverter controller can be programmed either using C/C++ or simulation software such as Simulink or PLECS. Thanks to a fully-automated code generation toolchain, the device can be programmed with just one single click!

The blocksets also embed simulation models so that the system can be accurately simulated and tuned before the code is generated.

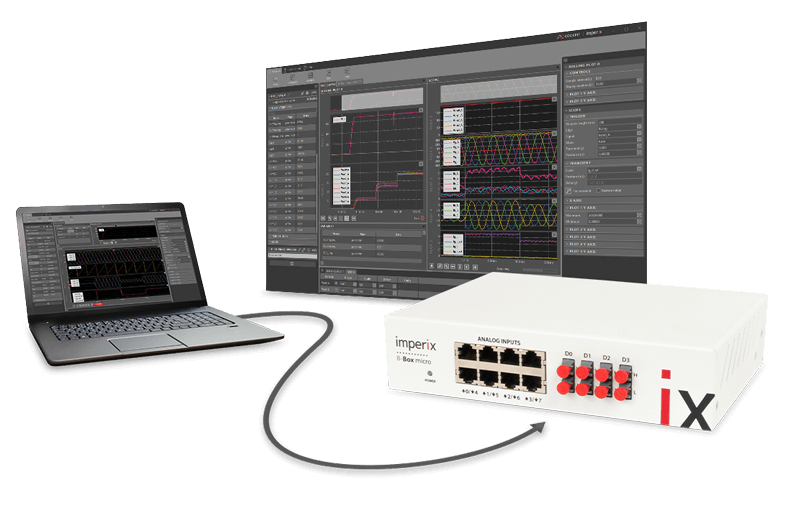

Specialized monitoring software

Imperix Cockpit is a Windows-based software included in both Software Development Kits (SDK). It allows observing, editing, and logging any variable present in memory in real-time.

This facilitates the rapid debugging and tuning of any converter control algorithms. The export of experimental data is also facilitated, speeding up the creation of reports and documentation.

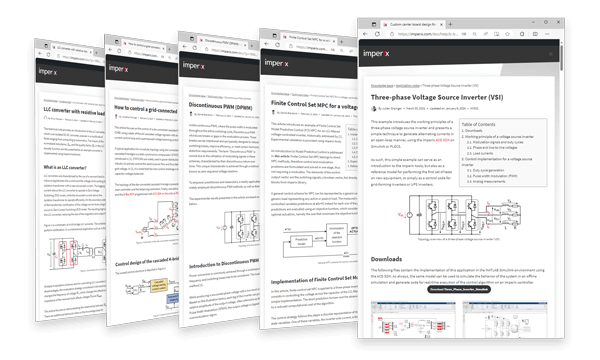

Ready-to-use application examples

The Imperix knowledge base gathers numerous technical articles as well as product-related documentation which is available for free. It includes:

- Product notes: Related to imperix hardware and software solutions.

- Application notes: Examples of systems and their operation.

- Software references: Provide documentation on all software blocks.

- Technical notes: Present solutions for the implementation of control software.

POWER INVERTER CONTROLLER

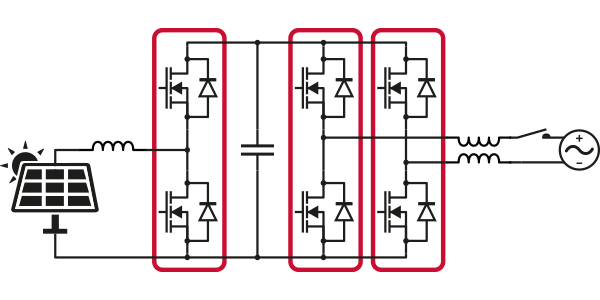

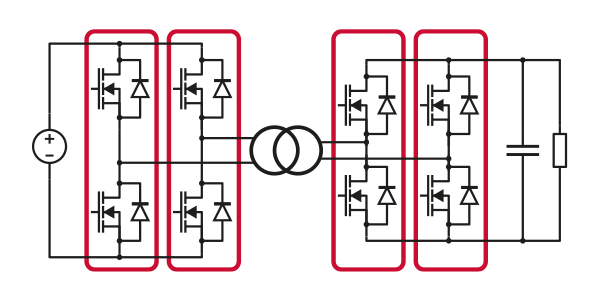

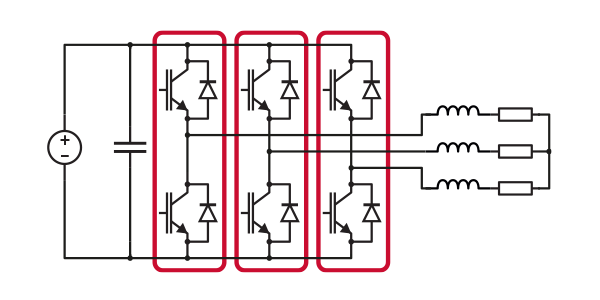

A BROAD RANGE OF APPLICATIONS

The B-Box Micro embeds a powerful processing system as well as sufficient I/Os to support a broad variety of applications. This notably enables using the same programmable controller for all teaching-related purposes, ranging from elementary converters to grid-connected inverters or high-frequency isolated converters.

Basic topologies

- Step-down converter (buck)

- Step-up converter (boost)

- Interleaved converters

Isolated DC/DC converters

- Flyback converter

- LLC resonant converter

- DAB converter

DC-AC converters

- Single-phase inverter

- Three-phase inverter

… and many more!

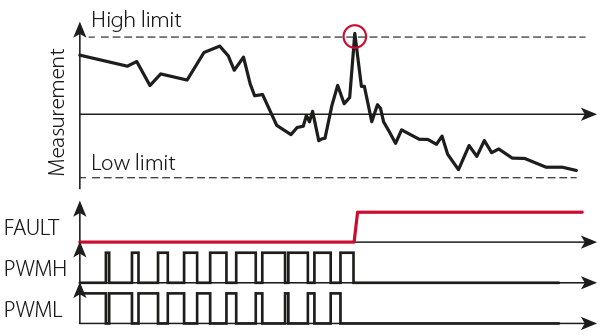

SAFETY FIRST !

A CONTROLLER THAT AUTHORIZES MISTAKES

In case of inappropriate operation, the controller instantly blocks its PWM signals, thanks to dedicated safety limits. They can be configured in software and guarantee reliable as well as fast-responding protection.

The B-Box Micro is also self-protected against inappropriate conditions such as excessive computational burden or algorithmic errors.

Classroom sessions

The B-Box Micro power inverter controller can be procured as part of a so-called starter kit, which contains the necessary products for building the most common converter topologies.

The starter kit is offered with an attractive volume discount, which is simultaneously compatible with the usual discount that is granted to academic institutions.

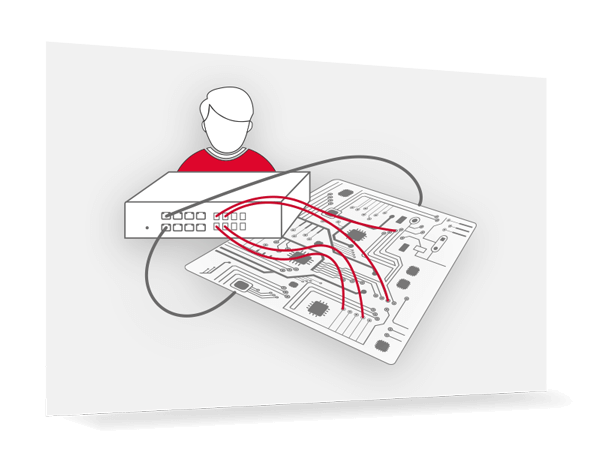

Individual projects

Students can also leverage the flexibility of the B-Box Micro for power converters that are not built using imperix modules, but rather a custom-designed PCB.

This is ideally suited for individual projects, in which students have to design their own converters, without loosing time on the control hardware implementation.

A CONTROLLER WITHOUT COMPROMISE

A HIGH-PERFORMANCE SYSTEM AT THE HEART OF EACH POWER INVERTER CONTROLLER.

The B-Box Micro relies on the same digital controller as the B-Box RCP 3.0, thereby sharing the same control performance. This guarantees consistent behavior and performance between different platforms, enabling users to switch seamlessly between them.

For a larger total number of I/Os, or compatibility with distributed control applications, B-Box RCP 3.0 is recommended.

High performance CPU

The B-Box Micro uses a dual-core processor (Xilinx Zynq). One DSP core is dedicated to the real-time control tasks (bare metal, dedicated kernel), the other one to the system supervision and monitoring (Linux). Most low-level tasks are also shifted in FPGA.

This results in the full dedication of a fast floating-point processor (DSP) to power converter control purposes, with tremendous performance, ranging up to 250 kHz control frequencies in closed-loop operation.

User-programmable FPGA

Absolutely no expertise in FPGA-based development is needed to work with this inverter controller. It operates readily with a highly flexible and highly configurable FPGA firmware.

Nevertheless, for the advanced users who require to alter the FPGA code, the B-Box Micro allows doing so. In this case, dedicated areas are provided, with straightforward integration within the existing DSP software kernel.

COMPREHENSIVE COMPUTER SOFTWARE

TOOLS DEDICATED TO THE CONTROL OF POWER CONVERTERS

Comprehensive design suites

Rapid control prototyping with our programmable controllers is supported by our software development kits (SDK), for either C++, Simulink or PLECS.

- Support for C++, Simulink, or PLECS

- Code libraries/examples

- Free maintenance

Monitoring & control software

During operation, Imperix Cockpit allows observing, editing and logging any variable. This facilitates the rapid debugging and tuning of any converter control code.

- Real-time tuning of all variables

- 2 million points datalogging

- Free maintenance