Controllers powering research, industrial & teaching applications

POWER ELECTRONIC CONTROLLERS

SPECIALIZED CONTROL SOLUTIONS

Fully-programmable DSP+FPGA digital controllers for power converters

Imperix offers a complete family of power electronic controllers, supporting the whole life cycle of power conversion systems, from rapid prototyping to commercial products.

Thanks to the high flexibility of their software and hardware, our power electronic controllers facilitate the prototyping and experimental validation of control techniques for all sorts of power converters.

DIGITAL CONTROLLERS FOR POWER ELECTRONICS

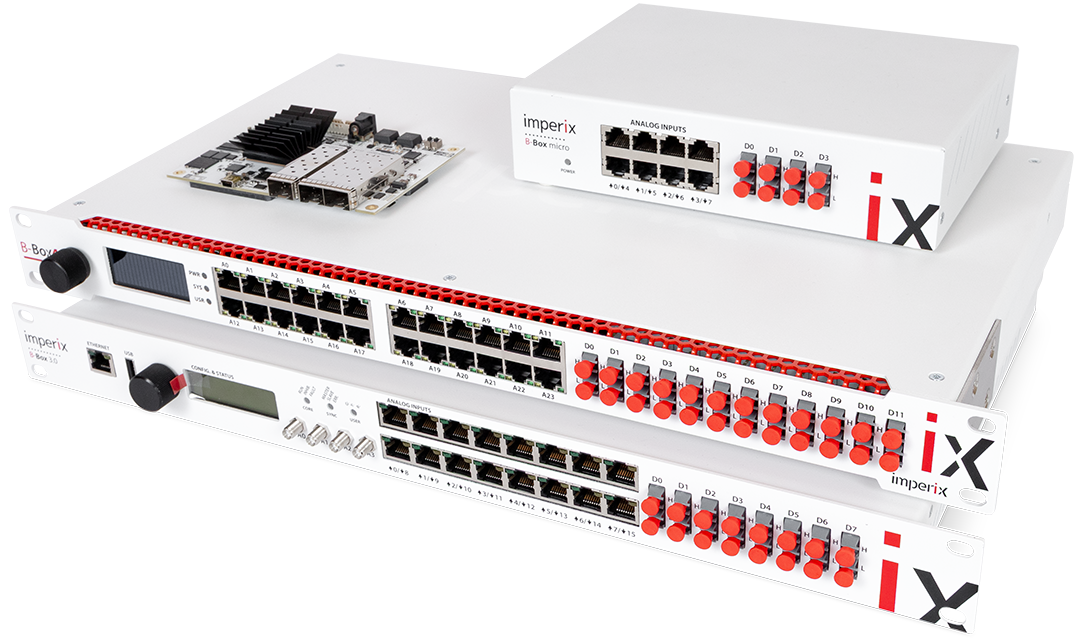

A COMPLETE FAMILY OF POWER ELECTRONIC CONTROLLERS

Our programmable controllers help engineers design, test, and validate digital control techniques for power converters. They enable them to save time during both development and product prototyping phases, thanks to their high level of specialization.

Typical applications include electric motor drives, grid-tied inverters (e.g. solar inverters), energy storage systems (e.g. batteries), or multilevel converters. Our control hardware includes four control systems for two distinct use cases:

- B-Box 4 is a high-performance rapid control prototyping system, supercharged with advanced scoping functions.

- B-Box RCP 3.0 is a rapid control prototyping system dedicated to research and development applications.

- B-Box Micro is a cost-effective table-top controller dedicated to teaching applications.

- B-Board PRO is a fully programmable controller that can be embedded inside industrial power converters.

PLUG-AND-PLAY CONTROLLERS

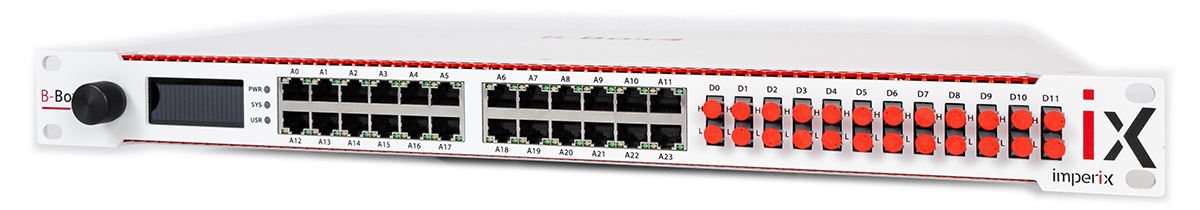

Flagship controller

- Class-leading analog frontend

- Numerous I/Os and protocols

- Suitable for distributed control

- Directly plug-&-play with imperix

power modules - Large FPGA, user-programmable

- Ultrafast, firmware-level protections

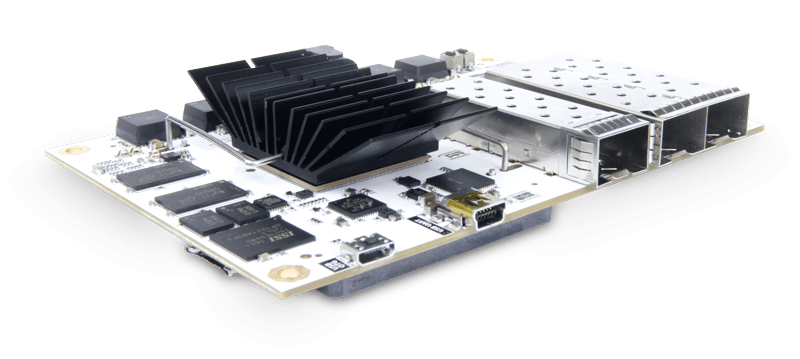

Industrial controller

- Embeddable, small form factor

- Numerous, board-level I/Os

- Suitable for distributed control

- User-programmable FPGA

- Software-level protections

Teaching-oriented controller

- Limited I/Os

- Directly plug-&-play with imperix power modules

- User-programmable FPGA

- Firmware-level protections

| B-Box 4 | B-Board PRO3.0 | B-Box Micro3.0 | |

| System on Chip | UltraScale+ (4x 1.5GHz + US+ Kintex 504K) | Zynq (2x 1GHz + Kintex 7 125K) | |

| Number of ADC-channels | 24x | 8x | 8x |

| Number of PWM-signals | 24x optical 48x electrical | 32x electrical | 8x optical |

| Number of USR I/O | 36x | 36x | 36x |

| Number of GPI/GPO | 24x / 24x | 16x / 16x | 16x / 8x |

| Distributed control (SFP) | |||

| Plug-&-Play compatibility | |||

| Programmable analog frontend | |||

| Protections | firmware-level, ultrafast | user-implemented | firmware-level |

A COMMON WORKFLOW WITH UNIFIED SOFTWARE

All imperix controllers can be used similarly and programmed using the same blockset or C/C++ functions. During testing, or when simply monitoring the system during operation, the same experience is also offered within imperix Cockpit.

1 – System programming

The digital controllers can be easily programmed using our automated code generation toolboxes for Simulink and PLECS, or by C/C++ coding.

All it takes to load a user code on a target hardware is only one click. Code generation, compilation, and upload are fully automated. Besides, no particular skills are needed.

2 – Run-time execution

The controllers can be used alongside a computer or as standalone devices. In both cases, direct access to the code execution is guaranteed by the Cockpit software.

All control targets can be used to build fully programmable power converters. Both the DSP and FPGA can be edited and have their parameters tuned during run-time.

3 – Live monitoring

The programmable controllers support real-time access, allowing engineers to monitor and tune any variable, which facilitates the debugging and/or maintenance of the control software.

The Cockpit software also provides extended datalogging capabilities similar to an oscilloscope. This allows logging every data point or observing control variables over longer time intervals.

EMBEDDABLE CONTROLLERS

What if you could simply take the result of your research and put it into an affordable controller, directly embedded inside your own power electronic systems?

DEVELOPMENT PHASE

- Flexible hardware

- Rapid control validation

PRODUCTION PHASE

- Cost-optimized hardware

- Product integration

Prototyping controller

The exact compatibility between B-Box RCP 3.0 and B-Board PRO power electronic controllers allows benefiting from the increased flexibility of the prototyping controller during development, while using a product-embeddable variant during series production.

Embeddable controller

B-Box 4

FLAGSHIP CONTROLLER FOR RAPID CONTROL PROTOTYPING APPLICATIONS

The B-Box 4 is an ultrafast and ultra-flexible power converter control system, tailored for rapid control prototyping of the power electronics applications of tomorrow. Thanks to its state-of-the-art performance, it facilitates the experimental validation of power converters control techniques, even for SiC and GaN-based converters.

Keywords:

- Rapid prototyping controller

- Inverter control hardware

- Electric motor drive controller

- Power converter controller

- Programmable inverter controller

- Built on AMD’s Zynq UltraScale+

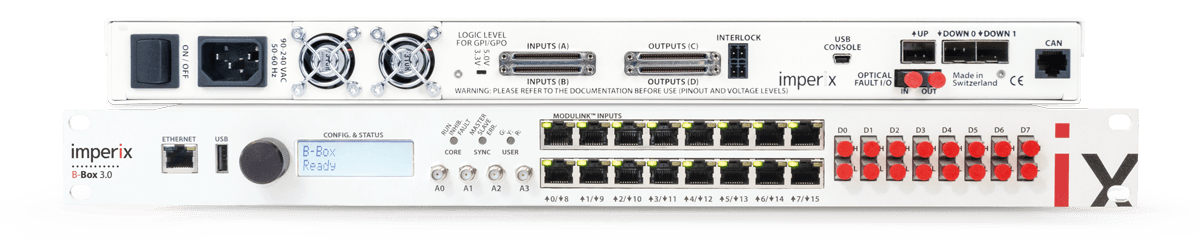

B-Box RCP 3.0

DSP+FPGA CONTROLLER FOR RAPID CONTROL PROTOTYPING APPLICATIONS

The B-Box RCP 3.0 is a highly flexible power converter control system, tailored for rapid control prototyping applications in power electronics. Benefitting from imperix’s high software and hardware flexibility, the B-Box RCP 3.0 facilitates the experimental validation of power converter control techniques in laboratory environments. This controller has a lower I/O count than the B-Box 4, but also reduced cost.

Keywords:

- Rapid prototyping controller

- Inverter control hardware

- Electric motor drive controller

- Power converter controller

- Programmable inverter controller

- DSP+FPGA control system

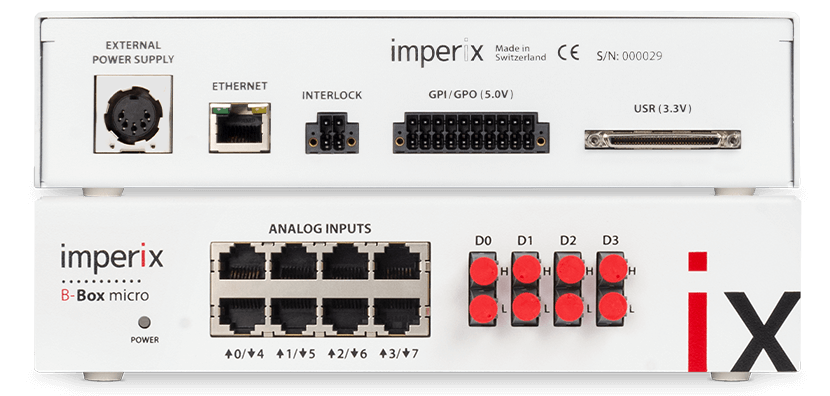

B-Box MICRO

TABLE-TOP CONVERTER CONTROLLER FOR TEACHING APPLICATIONS

The B-Box Micro is a small but mighty power inverter controller ideally suited for teaching applications. Its easy-to-use software environment makes it possible to switch faster from simulation to experimentation without taking any safety risks even for inexperienced users.

Keywords:

- Programmable inverter controller

- Table-top inverter controller

- Power converter controller

- DSP+FPGA control system

- Teaching power electronics

- Power laboratory equipment

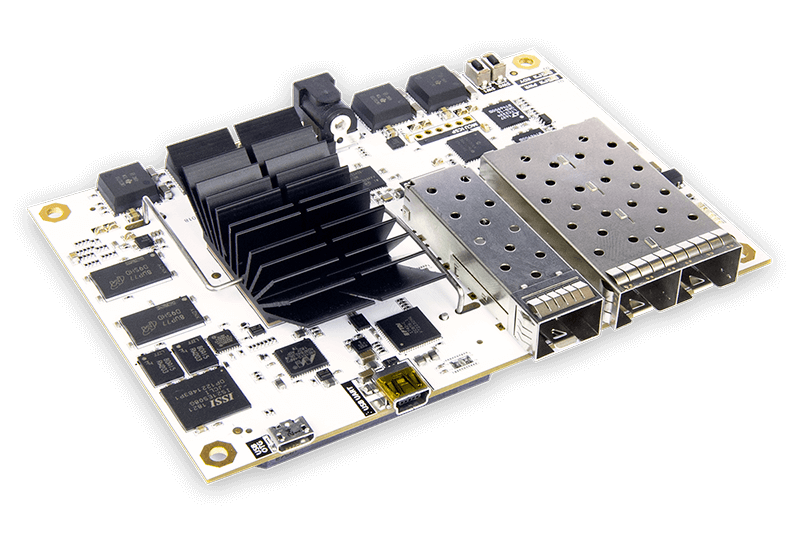

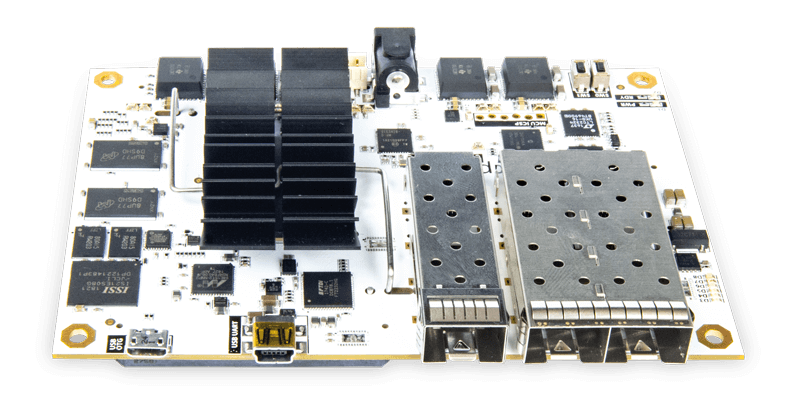

B-Board PRO

CONVERTER CONTROLLER MODULE FOR PRODUCT-EMBEDDED APPLICATIONS

The B-Board PRO is the heart of the B-Box 3 controller but it is also available as a standalone controller for embedded applications. The board feature a ZynQ-based dual-core ARM processor and a Kintex-grade FPGA (Xilinx Zynq), plus advanced communication capabilities and extensive I/Os.

Keywords:

- Embedded control board

- Programmable digital controller

- Converter control hardware

- DSP+FPGA control module

- Power inverter control module

TO GO FURTHER

Software solutions

The Automated Code Generation (ACG) SDK enables engineers to program the power electronic controllers directly from Simulink or PLECS. The provided toolchain handles fully automated code generation, compilation, and upload in just one click.

In addition, the SDK contains simulation models of each controller peripheral, so that the exact behavior of the control system can be simulated – and hence easily anticipated – before code is generated.

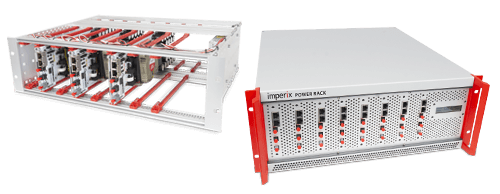

Power equipment

Imperix power modules are ready-to-use building blocks allowing to build up almost any converter topology. They exist in various power ratings and internal structures. Each module features:

- Power semiconductors

- Gate drivers

- Voltage and current sensors (with local protection)